External circulation is used in a range of applications involving heating or cooling in external systems. In this post, we explore some of the equipment available for external circulation and the factors to consider when choosing your unit.

External Circulation Equipment

Many circulating baths are capable of both internal and external circulation. Some come with the option of only having external circulation available (where the bath is closed off completely).

For example, the JULABO Ultra-Low Refrigerated Circulator comes with the option to have the bath available for internal circulation (left) or have it closed off (right).

Some are designed for external circulation only, such as the above PolyScience Model 210 Heated Recirculator.

Factors to Consider When Choosing a Circulating Bath

When selecting a bath for an external circulation application, here are the factors you need to bear in mind:

Pump Pressure

Depending on the system you’re using, you’ll need to ensure your unit’s pump is capable of enough pressure to sufficiently circulate the liquid. For example, some factors which can cause a drop in pressure include the length, height, and bore of pipes, and the number of bends involved. The greater the restriction, the higher the pressure that will be required.

If you don't maintain adequate liquid flow rate, you risk being unable to maintain the required level of heat exchange in your external system.

An added perk in some systems is variable pump speed. Having the option to adjust the speed means you can compensate for fluid viscosity and adjust the flow rate as needed.

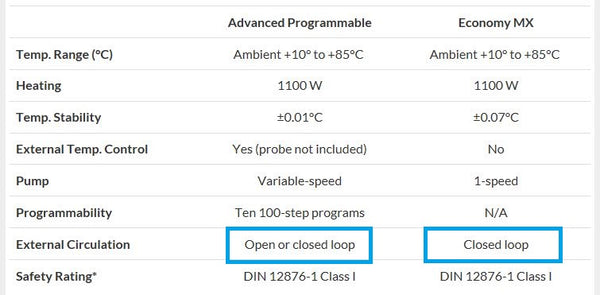

Many of the PolyScience Integrated Heated Baths come with a variable-speed pump.

Open- vs. Closed-Loop Circulation

External circulation can be closed-loop or open-loop. Closed-loop circulation involves the fluid being pumped from the circulator through an external device, such as a water jacket or condenser, and then returning directly to the circulating bath.

Open-loop circulation involves the liquid being pumped to an open tank, and liquid from that tank being returned to the bath.

The main difference in terms of equipment is the type of pump required for each type of circulation:

- Closed-loop circulation only involves pressure so can usually be achieved using a pressure-only (simplex) pump. If additional pressure is needed, you may require the use of a duplex pump.

- Open-loop circulation uses pressure to push liquid out and suction to pull it back. This means a pump capable of both pressure and suction (a duplex pump) is required.

Specifications for the PolyScience Polycarbonate Open Bath System 17 Liter. The Economy MX model is capable of closed-loop circulation only, but the Advanced Programmable model is capable of both open- and closed-loop external circulation.

Heating or Cooling Capacity

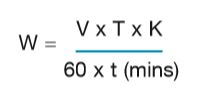

Manufacturer specifications for a unit will tell you how much cooling or heating capacity it is capable of. For external systems, it can be tricky knowing how much heating or cooling capacity you will need from your circulator. This simple equation can help you decide:

where:

- W = average cooling power

- V = total system liquid volume (L)

- T = temperature difference °C

- K = liquid heat capacity (J/L/°C)

That being said, this doesn’t take into account the insulation of the external system or the heat load, if any, being applied by external processes. While this formula can serve as a guide, when looking for a suitable circulating bath, it’s prudent to tack on a reasonable amount of wattage to be on the safe side.

Note that in the manufacturer specifications for circulating baths, cooling capacity is provided for specific liquids (often water or ethanol) and temperatures. You can use the above equation to find out the cooling or heating capacity of your unit under different conditions.

Temperature Ramping

Some circulating baths give you the ability to control time and temperature precisely. For example, you can program temperature ramping followed by specified soaking periods. This can be important in various scenarios, such as material testing applications where a sample needs to be heated or cooled over a fixed, known period of time.

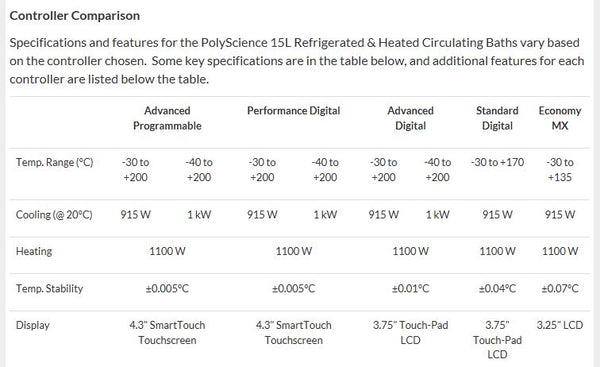

Many PolyScience baths come with a choice of different controllers, some of which allow for ramping. Other features of these controllers include event scheduling and multi-point calibration capability.