An important specification to look at when selecting a chiller for your application is its cooling capacity. If your cooling capacity is too low, your chiller won’t be able to reach and hold its setpoint temperature.

In this post, we explain what cooling capacity is and what factors affect it. We’ll also discuss how to determine what cooling capacity you need for your application, including how to convert between common units used for the metric.

What Is Cooling Capacity?

Cooling capacity measures the ability of a cooling system to remove heat. The SI units for cooling capacity are watts (W), but it may also be denoted in British Thermal Units per hour (BTU/hr) or tons of refrigeration (RT).

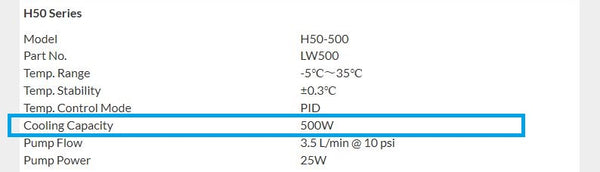

Manufacturer specifications for the H50-500 Recirculating Water Chiller.

The cooling capacity of a chiller decreases with the set temperature. When the setpoint is lower, there is a smaller temperature differential between the refrigerant and chiller liquid. As a result, there is less efficient heat transfer, which translates to decreased cooling capacity.

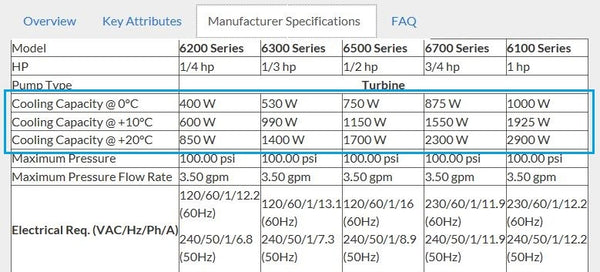

As such, manufacturer specifications for a given unit will often show the cooling capacity at a specific temperature. Some manufacturers will provide multiple cooling capacities at various temperatures.

Manufacturer specifications for some of the 6000 Series Portable Chillers.

Factors Affecting the Cooling Power of a Chiller

We mentioned set temperature above, but this isn’t the only factor that can have an effect on the cooling capacity of a chiller. Here are some other considerations:

Ambient (or Facility Water) Temperature

During the refrigeration cycle, the condenser transfers heat from the hot refrigerant to the ambient air or facility water, depending on the type of chiller. For air-cooled condensers, the higher the temperature of the air, the smaller the temperature differential between the air and the refrigerant, and the more difficult it is for heat to be expelled.

It’s a similar case for water-cooled condensers. Higher temperature facility water will result in less efficient heat transfer and decreased cooling capacity.

Cooling capacities listed in manufacturer specifications typically correspond to an ambient air temperature of 20°C or a facility water temperature of 20°C.

Maintenance

A less obvious factor that can affect cooling capacity is chiller maintenance. With air-cooled condensers, buildup of dust and debris on fins and fan blades can inhibit air flow, lowering the cooling capacity.

For water-cooled condensers, scale formation, corrosion, or biological growth can reduce heat transfer, again lowering the cooling capacity.

To avoid these issues, you can perform regular maintenance on your chiller as appropriate, including cleaning the condenser fins, using a corrosion inhibitor, and flushing the coolant.

Determining How Much Cooling Capacity You Need

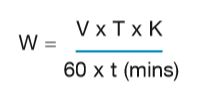

So how much cooling capacity do you need for your application? While it’s not a foolproof method, the following equation can serve as a good guide:

Where:

- W = average cooling power (W)

- V = total system liquid volume (L)

- T = temperature difference (°C)

- K = liquid heat capacity (J/L/°C)

This formula can be helpful, but it’s a good idea to add on at least 20 percent more wattage to be on the safe side. After all, it’s highly unlikely that any system is going to be 100 percent efficient. Plus, there are external factors to consider such as ambient heat gain due to imperfect insulation, fluctuation of the facility water or ambient air temperature, and the aforementioned maintenance issues. Note that this formula doesn’t account for insulation of external systems, or any heat load that may be applied by external processes.

Manufacturer specifications list the cooling capacity for specific liquids, usually water or ethanol. The above equation can also be used to calculate the cooling capacity for different conditions.

How to Convert Between Different Cooling Capacity Units

As mentioned, the most common unit used for cooling capacity is the watt (W), with British Thermal Unit per hour (BTU/hr) and ton of refrigeration (RT) being the two main alternatives.

If you need to switch between between any pair of these units, here are the conversions:

- 1 RT = 12000 BTU/hr

- 1 BTU/hr = 8.33333 ×10-5 RT

- 1 BTU/hr = 0.29307107 W

- 1 W = 3.412142 BTU/hr

- 1 W = 0.000284345 RT

- 1 RT = 3516.85 W