When choosing a bath for your application, you have a couple of key decisions to make, including what type of bath to use and what liquid or material to use in it. There are various types of bath to choose from, including water baths, bead baths, and more. What’s more, if you choose to go with a water bath, you aren’t restricted to using just water in it. You can often use oils, sand, or beads in a water bath too.

The type of bath you choose and the liquid or material you decide to put in it will depend on various factors of your application, including what temperature you’re working with and the vessels you’re using.

In this post, we’ll discuss the different types of baths available and what applications they’re best suited to.

Deciding Between Using a Liquid or Solid in the Bath

One of the first things you need to look at is whether you would be best off using a liquid or solid bath material. Note that although you’ll find many baths listed as water baths or oil baths, many are suitable for use with other liquids and some solid materials, such as beads or sand.

The following table shows you some of the main differentiating factors between the some types of bath liquids and materials, but we’ll go into more detail about these below.

|

Water Bath |

Oil Bath |

Bead Bath |

Sand Bath |

|

|

Low Cost |

Y |

N |

N |

Y |

|

High Thermal Efficiency |

Y |

Y |

Y |

N |

|

Microbial/Biofilm Resistant |

N |

Y |

Y |

Y |

|

Cross-Contamination Resistant |

N |

N |

Y |

N |

|

Minimal Cleaning Required |

N |

N |

Y |

Y |

|

No Refilling Required |

N |

N |

Y |

Y |

|

Rack and Accessory Free |

N |

N |

Y |

Y |

|

Angled Incubation Possible |

N |

N |

Y |

Y |

|

No Evaporation |

N |

Y |

Y |

Y |

|

Non-Corrosive |

N |

Some |

Y |

Y |

|

Broad Temperature Range (-80 to 180°C) |

N |

Y |

Y |

Y |

|

Compatible with Non-Watertight Vessels |

N |

N |

Y |

Y |

|

Always On (No Warm Up) |

N |

N |

Y |

Y |

|

Combustion Risk? |

N |

Some |

N |

N |

Using Liquid in a Bath

When using liquid in a bath, you’re not just limited to water, and with a range of bath liquids available, you have a broad temperature range to work with. We’ll go into more detail about specific liquids below, but let’s just say that liquid baths are flexible when it comes to setpoint temperatures.

An advantage of a liquid medium is that there is a greater surface area in contact with the vessel than there would be if you were using beads in the bath. This means that the sample will heat up more quickly and the heating will be more uniform.

A myBath Series 2 Liter and a PolyScience Digital General Purpose 5 Liter Water Bath.

Liquid baths don’t come without their downsides. They are prone to contamination, especially those containing water, as they can create the perfect environment for promoting the growth of many strains of bacteria. Although, some synthetic bath liquids are much less prone to contamination than water.

The contamination problem means that liquid baths are not particularly suitable for aseptic applications. They’re also not good for RNA applications due to the potential for RNAases to be present in contaminated bath fluids.

Within the category of water baths, you have different types to choose from, such as standard heated baths, refrigerated baths, and high temperature baths. Although, in the latter, you’ll be more likely to use oil as the bath liquid.

Using Dry Materials in a Bath

Baths that don’t involve the use of water, and instead use dry materials, such as beads, are more hygienic. Even if there is contamination present, with no water, it’s less likely that contaminants will spread to the sample. As with a water bath, you can use vessels of any size. Note that some baths are designed specifically for use with solid materials, but you can often use beads or sand in a water bath.

Bead Baths

Perhaps surprisingly, bead baths can offer a broad temperature range -- the one below can handle setpoint temperatures between -80°C and 180°C. Bead baths heat up quicker than water baths and can be left on as you don’t need to worry about evaporation.

A Lab Armor Digital Bead Bath 6 Liter.

Other benefits of using a bead bath are that they don’t require refilling, you don't have to worry about corrosion, and racks and other accessories are unnecessary.

The main downside to using a bead bath is that there isn’t as much surface area in contact with the vessel as there would be with a liquid. Therefore, heating is slower and less even. For small vessels this may be barely noticeable, but for large (> 500 ml) or frozen vessels the difference in heating time may be significant – as much as 2–3 times longer.

Sand Baths

Another option is to use sand in a water bath. With this method, you get some of the advantages of bead baths such as minimal cleaning, no corrosion concerns, and no need for racks or accessories. Additionally, sand particles are far smaller than beads helping with more even heating. Another plus is that sand is very inexpensive.

Sand can be used in very high-temperature applications, but its thermal efficiency is lower than that of metal beads. Plus, it can be messy and more difficult to clean up afterwards than bath beads or most bath fluids.

What Liquid Should You Use?

If you do decide to go with a water bath, you need to decide on the appropriate liquid to use in it. Some things to consider in your decision are:

- Compatibility of the liquid with the equipment

- Viscosity of the liquid (high-viscosity liquids can be difficult to work with)

- Freezing temperature of the liquid for cooling applications

- Boiling temperature of the liquid for heating applications

Water is often the most preferable liquid as it is inexpensive, non-toxic, and easily accessible. But of course, it only works within a specific temperature range. For temperatures close to 100°C, you’ll see boiling and quick evaporation. For temperatures below 10°C, you may get icing. Thankfully, there are many alternative options.

Heating Applications

If you need to use a bath at temperatures near or above 100°C, instead of using water in the standard bath, you can use oil (silicone oil is popular) or another high-temperature bath liquid (see Specially-Formulated Bath Liquids below).

Silicone oils vary in viscosity and can be used for a broad range of temperatures. The precise temperature range for each oil depends on its viscosity. For example, a low viscosity oil might have a range of -40–130°C, while a high viscosity oil might be usable between 25–230°C. Mineral oil is another option and has similar properties to silicone oil.

You may be wondering how suitable cooking oils would be for use in a bath. While they are inexpensive, non-hazardous, and readily available, they’re far from ideal. Due to the relatively high kinematic viscosity of cooking oils, they don't flow all that well, leading to uneven differences in temperature within the bath. This has the potential to put additional stress on the bath's heater.

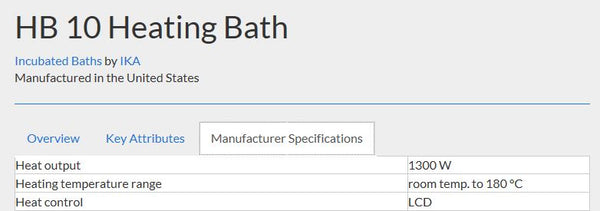

While some standard water baths can be used with oil, you might instead consider a high temperature bath (often called an oil bath) that is designed specifically for high-temperature applications. For example, the bath below has a heating temperature range of room temperature to 180°C, and can be used with water or oil, as can all high-temperature baths.

Manufacturer specifications for the HB 10 Heating Bath.

Cooling Applications

If you’re using a standard bath for cooling below 10°C, you’ll need an alternative to water that has a freezing point lower than your setpoint temperature. In the case of recirculating chillers, the temperature inside the equipment may be much lower than the setpoint temperature. Therefore, you should choose a liquid with a freezing temperature at least 20°C lower than your setpoint temperature.

Often, in cooling applications, water is used with another liquid to produce a mixture that offers a temperature range more suitable for the application. We’ll describe those liquids briefly here, but you can see more information about the freezing and boiling point of the liquids and their solutions in the table below.

- Ethanol and methanol are both non-viscous and non-corrosive, and have low freezing points. However, they evaporate quickly and are flammable.

- Ethylene glycol is more versatile because it has a low freezing point and high boiling point, so you could use it for a range of applications. However, ethylene glycol is toxic, which affects storage, handling, and disposal.

- Propylene glycol is similar to ethylene glycol but is less toxic. However, it can oxidize to form a corrosive acid -- if it has a red color it needs to be replaced.

- Glycerol is non-toxic but is more viscous than the other liquids on this list, so it’s not as easy to handle.

|

Freezing Point |

Boiling Point |

|

|

Water |

0 |

100 |

|

Ethanol |

-114 |

78 |

|

Water/Ethanol 50:50 |

-32 |

92 |

|

Methanol |

-98 |

65 |

|

Water/Methanol 50:50 |

-54 |

76 |

|

Ethylene Glycol |

-13 |

197 |

|

Water/Ethylene Glycol 50:50 |

-34 |

107 |

|

Propylene Glycol |

-59 |

188 |

|

Water/Propylene Glycol 50:50 |

-33 |

107 |

|

Glycerol |

17 |

290 |

|

Water/Glycerol 50:50 |

-23 |

107 |

Specially-Formulated Bath Liquids

If you’d rather not make your own water bath liquid blend, you can opt to buy special liquids from manufacturers. For example, PolyScience manufactures a range of Polytherm fluids for high-temperature applications and Polycool fluids for low-temperature applications.

The below table shows the different variations available and what temperature ranges they cover, along with their prices.

|

Title |

Temperature |

|

Polytherm S150 |

50°C - 150°C |

|

Polytherm S200 |

100°C - 200°C |

|

Polytherm S250 |

150°C - 250°C |

|

Polytherm M170 |

50°C - 170°C |

|

Polycool HC-50 |

-50°C - 100°C |

|

Polycool EG-25 |

-25°C to 100°C mixed 50%/50% with distilled water |

|

Polycool PG-20 |

-20°C to 100°C, mixed 50%/50% with distilled water |

|

Polycool MIX-25 |

-25°C to 100°C |

Depending on which you opt for, these may have the benefits of being non-toxic, non-corrosive, stable, and highly conductive. Of course, this is a more expensive route than making your own blends.